TunellOpDmiz

Portfolio Website of Andrew Tunell

Engineer, Researcher, and Creator

I’m Andrew Tunell, a PhD candidate in Mechanical Engineering at UT Austin. I work on nanoscale surface adhesion, dust-mitigating nanostructures for space exploration, and hands-on engineering projects ranging from home-lab servers to custom hardware.

About Me

I’m always open to new opportunities, collaborations, and conversations. You can learn more about my experience or contact me directly through the link below.

Engineering Projects

I design and build hardware systems that merge mechanics, electronics, and software. This includes nanoscale research tools, microcontroller-powered automation, and 3D-printed prototypes that make everyday tasks more innovative and reliable.

Please check my engineering page below for more!

Featured Works

-

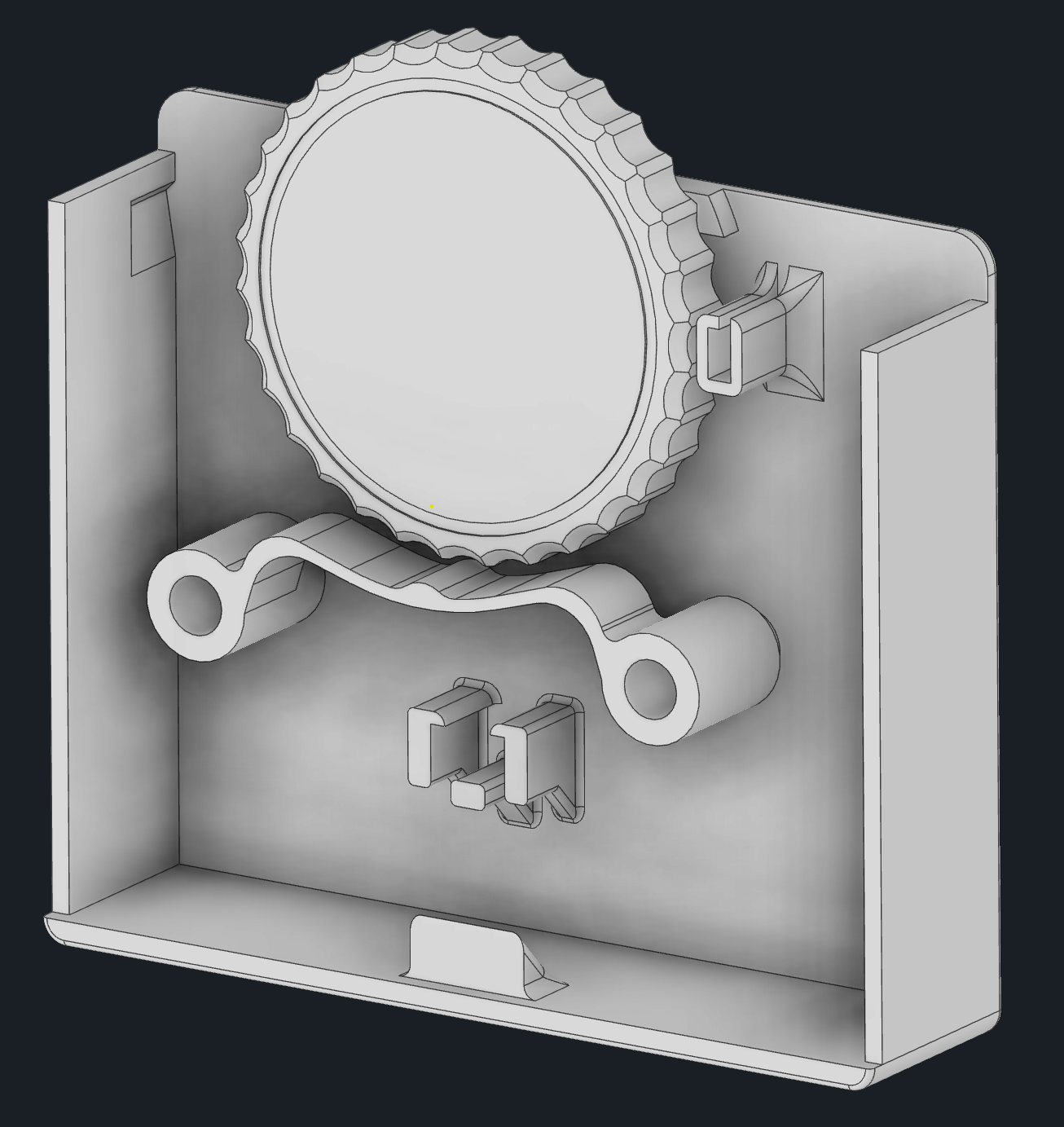

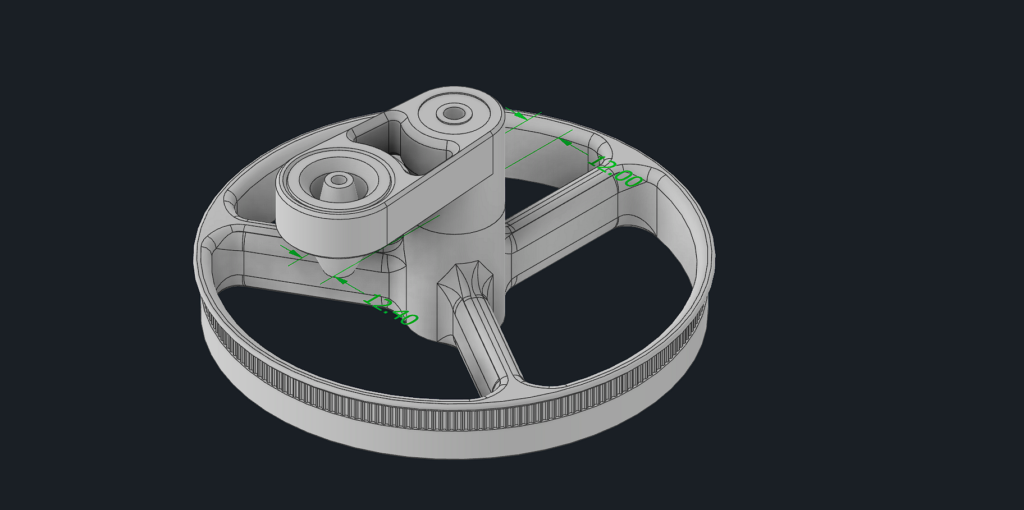

Home Control

This model includes an ESP-32, an I2C OLED display, a hall-effect sensor, and an endstop/button. The fun challenge I implemented in this design was building my own encoder wheel solution. For this I created a wheel which had a series of embedded magnets in the perimeter. Using a Hall effect sensor mounted next to the…

-

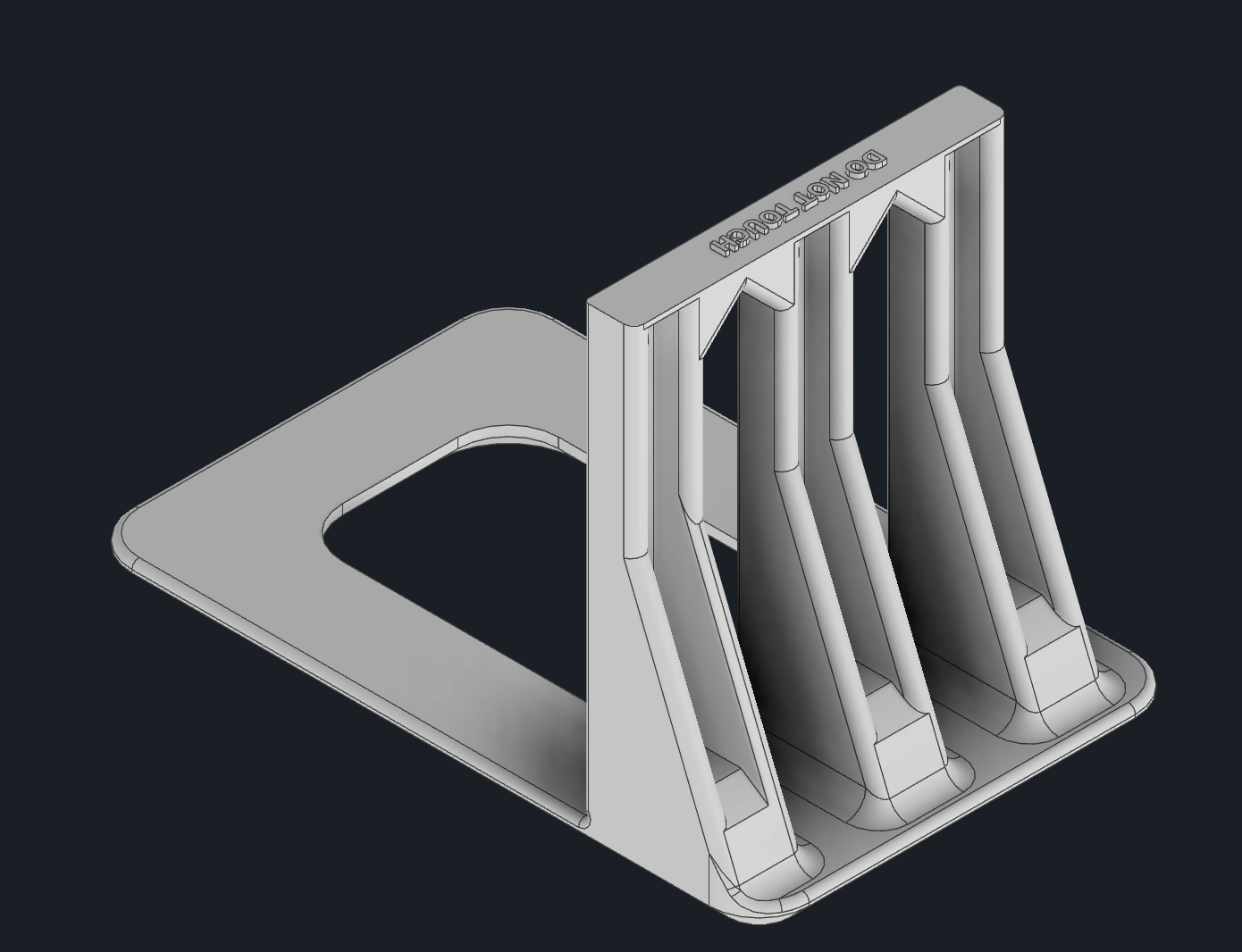

HDD External Mount

This model allows for 3 hard drives to be mounted vertically and in the open. This was an admittedly strange necessity for me; however, my server chassis has been entirely filled with other components, so I had to move the hard drives outside. I wanted them open so they could receive passive cooling from the…

-

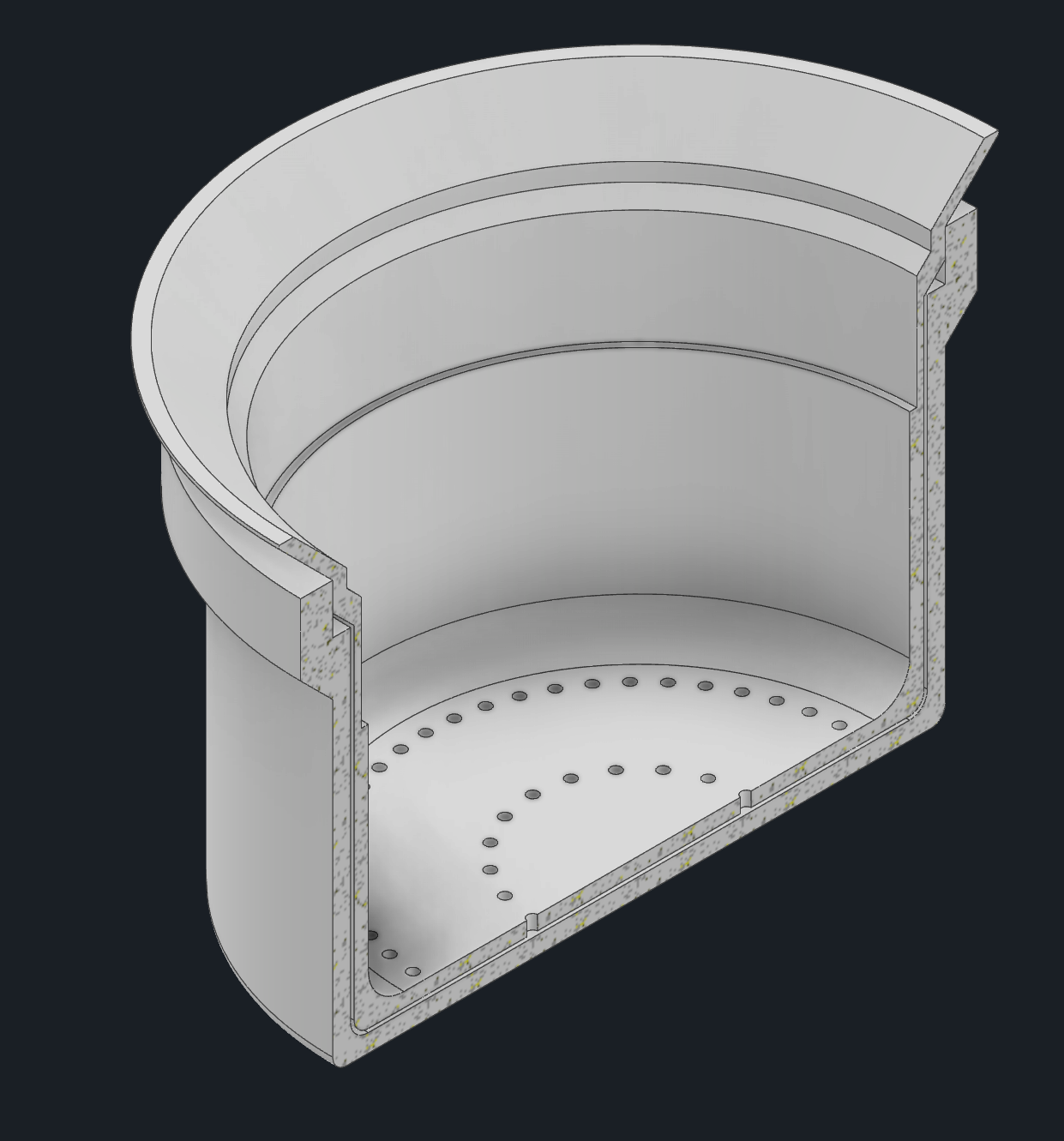

Easy Rice Measurement Cup

This cup is dual layered. The inner layer has drainage holes at the bottom and a fill line on it. You fill the inner cup with rice up to the fill line, while in the outer cup – and can rinse the rice without it draining. After you can remove the outer cup and the…

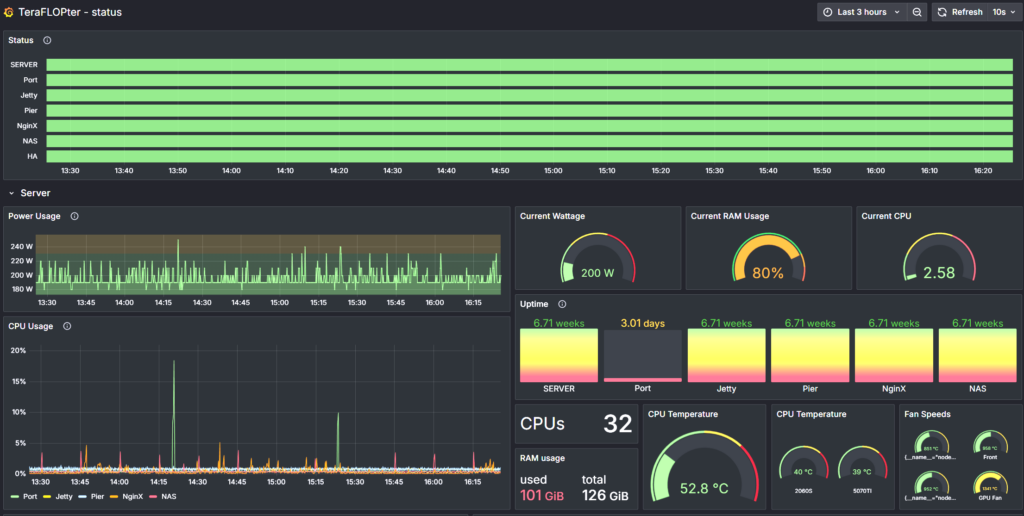

AI and Software

I build tools that blend local AI, automation, and custom code to solve real problems. From running models on my home server to creating full pipelines for image generation and smart devices, I focus on practical, fast, and flexible software.

Research and Publications

My work focuses on nanoscale adhesion, dust-mitigating surface structures, and electrostatic interactions in lunar environments. I publish across experimental surface science, nanomanufacturing, and applied modeling, with an emphasis on turning fundamental physics into practical engineered surfaces.

Please check below for my Google Scholar – or my Highlighted works page!

Featured Works

-

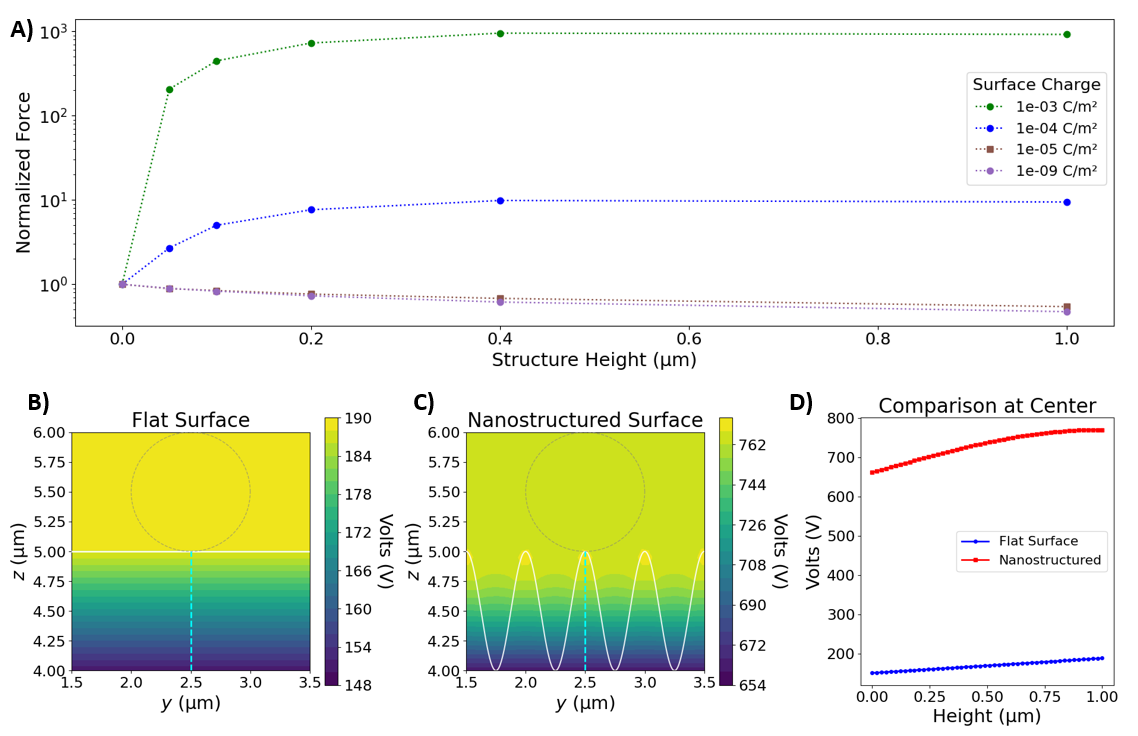

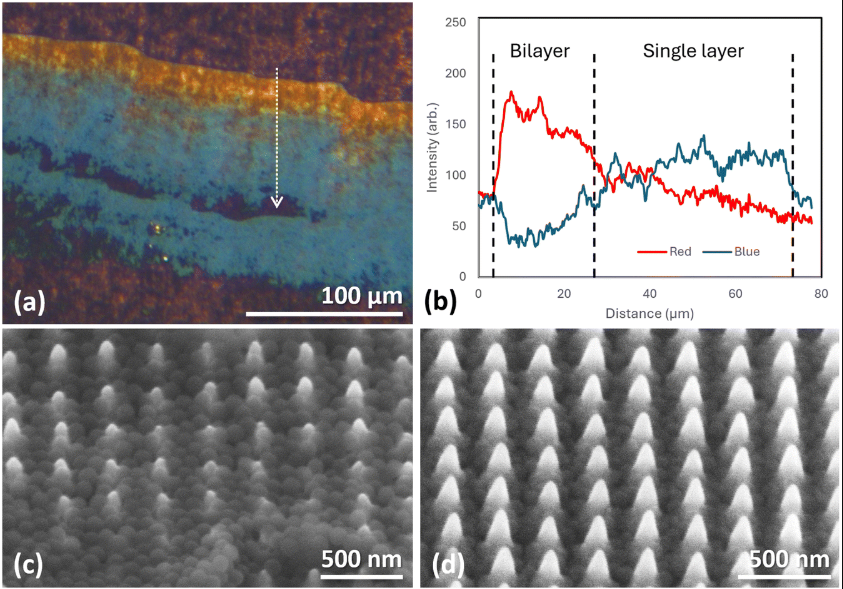

Investigation of electrostatic effects between charged particles and nanostructured surfaces

https://doi.org/10.1116/6.0004977 Abstract In this work, the effect of nanostructures and surface coatings on the effective electrostatic force acting on a particle resting on the surface is investigated. A proposed analytical model based on Coulomb’s law predicts that electrostatic forces on a particle decrease with the addition of nanostructures due to increased separation distance. Additional comsol simulations were…

-

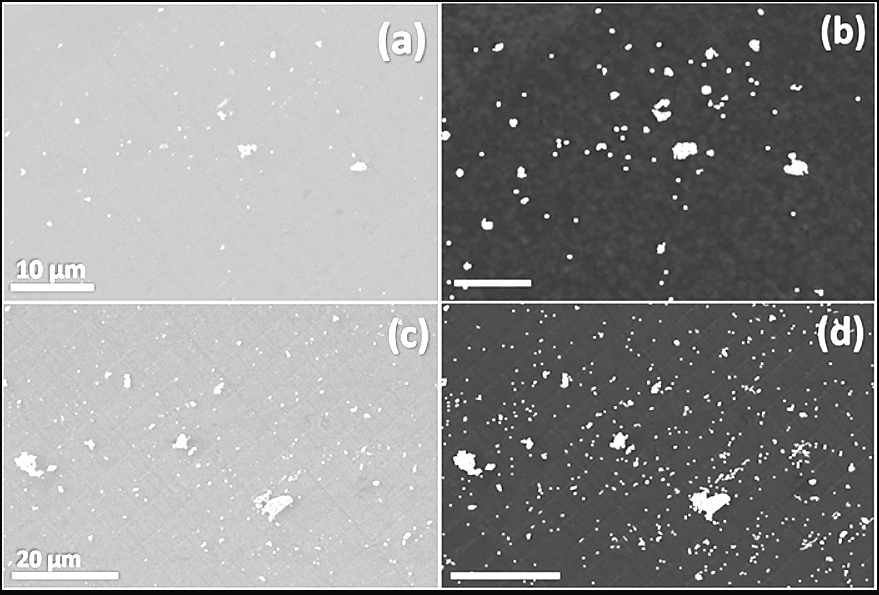

Identification of dust particles on a periodic nanostructured substrate using scanning electron microscope imaging

https://doi.org/10.1116/6.0003043 Abstract Dust-mitigating surfaces typically consist of high-aspect-ratio structures that separate particles from resting on the bulk material, thereby limiting adhesion due to short-range van der Waals forces. These surfaces can find uses in solar-panel coatings and a variety of dust-resistant optics. The current method for quantifying surface contamination is optical microscopy, but this method…

-

Nanoparticle dispersion and separation in superhydrophilic nanostructures

https://doi.org/10.1039/D5LF00089K Abstract Nanostructures can have novel properties that are rarely found in macroscale materials and have been employed for a wide range of applications. The wetting properties of nanostructured surfaces are particularly interesting and are controllable by engineering structure geometry and surface chemistry to create hydrophobic or hydrophilic nanostructures. In this work, we investigate the…

Anthill Pottery

Artwork

I am an avid potter and painter! I have been throwing on the wheel since I was 14, and painting since birth!

I hav

I have been doing pottery since I was 14 years old, when I found a love for it at Booker T. Washington High School for the Visual and Performing Arts in downtown Dallas.

I left Booker T. as I wanted a more STEM-focused education to prepare me for a degree in engineering. Therefore, I transferred to Bishop Lynch High School in Dallas. However, my thirst for a creative outlet was not satisfied until I began pottery throwing classes at CAC Dallas, with an excellent teacher, I fell in love, and the rest is history.

After several years of classes at CAC, I decided I was ready to work on my own. I was gifted a pottery wheel from one of my neighbors, and purchased a kiln on eBay.

This was the foundation of Anthill pottery.

I sold ceramic pieces on ETSY for several years, but as I went to college, balancing my school work and operating my ceramics business became very difficult (as they were in different cities).